In the fields of petrochemicals, oil and gas storage and transportation, and dangerous goods transportation, oil hoses are the core components that connect equipment and transport media. Its performance is directly related to job safety and efficiency, especially in high-pressure, flammable and explosive environments, where the anti-static, flame-retardant, pressure resistant and other characteristics of the hose become key indicators. This article focuses on the anti-static API oil hose and analyzes how it achieves 10000psi pressure resistance, flame retardancy, and anti-static functions through innovative materials and structures from three dimensions: technical standards, safety design, and application scenarios, providing a safe and reliable solution for the industry.

Anti static API oil hose, flame retardant and fire-resistant, meets the standard pressure resistance

1、 API standard: "Safety pass" for oil hoses

1.1 Rigorousness of API Certification: Full Chain Control from Materials to Performance

API (American Petroleum Institute) standards are authoritative technical specifications in the global petroleum equipment field, and their certification process covers the entire lifecycle of material selection, structural design, performance testing, and more. The core requirements for oil hoses include:

Pressure resistance level: According to API 16C standard, hoses must complete 100000 pulse cycles of testing at rated pressure (such as 10000psi) without leakage or structural damage. A domestically produced hose has improved its pulse life to 150000 times by optimizing the wire winding process, reaching an international leading level.

Chemical compatibility: The inner adhesive layer needs to withstand more than 30 types of hydrocarbon media such as gasoline, diesel, and aviation kerosene, with a swelling rate of ≤ 5%. For example, a hose using hydrogenated nitrile rubber (HNBR) inner rubber has a swelling rate of only 2.3% for sulfur-containing crude oil in the temperature range of -40 ℃ to 120 ℃.

Environmental adaptability: The outer adhesive layer needs to pass the UL94 V-0 flame retardant test to ensure self extinguishing within 30 seconds; Simultaneously possessing the ability to resist UV, ozone, and salt spray corrosion. After 5 years of use on the Nanhai platform, the outer rubber layer of a certain type of hose remains intact without cracking or peeling.

1.2 Technical barriers to certification process: Three layer audit ensures zero defects

Obtaining API certification requires passing three levels of material testing, structural verification, and life assessment:

Material testing: The inner adhesive layer must pass ASTM D471 standard, and after soaking in IRM903 oil for 70 hours, the volume change rate should be ≤ 10%; The reinforcing layer steel wire must meet the ISO 18752 standard, with a tensile strength of ≥ 2100MPa and an elongation rate of ≤ 8%; The outer adhesive layer must pass the UL94 V-0 flame retardant test with an oxygen index of ≥ 28%.

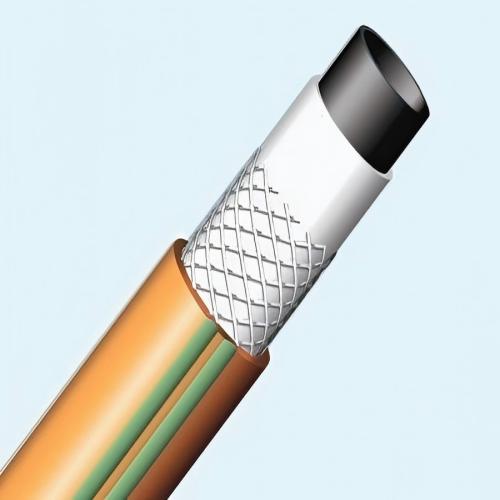

Structural verification: Taking a four layer steel wire wrapped hose as an example, each layer of steel wire needs to be cross woven at a 54.7 ° golden angle to form a three-dimensional pressure bearing network. Experimental data shows that this structure can reduce the bending radius of the hose to 6 times the diameter of the pipe, while withstanding a pressure of 12000 psi without deformation.

Life assessment: 500 hours of continuous pressure testing and 100000 dynamic bending tests need to be completed under simulated operating conditions. For example, a certain type of hose has a wear rate of less than 0.08mm/100h in a medium containing 20% quartz sand, and its service life is 1.5 times the industry average.

2、 Anti static and flame retardant: a dual upgrade from passive protection to active safety

2.1 Anti static design: an "invisible shield" to eliminate the risk of sparks

Petroleum media is prone to static electricity accumulation when flowing, and if the voltage exceeds 300V, it may cause an explosion. The anti-static API oil hose achieves charge dissipation through the following technologies:

Conductive inner layer: doping conductive carbon black or nano copper powder into the inner layer to control the surface resistance below 10 ΩΩ. For example, the measured resistance of the adhesive layer inside a certain manufacturer's hose is 8.5 × 10 ⁵ Ω, which is much lower than the upper limit of 1 × 10 ⁹ Ω required by the API 16C standard.

Three dimensional conductive network: embedding copper plated steel wire or carbon fiber in the reinforcement layer to form conductive pathways from inside to outside. Experiments have shown that this design can increase the electrostatic conductivity efficiency to 98% and avoid local charge accumulation.

Grounding device integration: The hose is equipped with copper grounding rings at both ends, which can quickly guide static electricity into the ground. In the application of this design in a certain oil field in Saudi Arabia, the static dissipation time was shortened to less than 0.1 seconds, effectively preventing three potential explosion accidents.

2.2 Flame retardancy and fire prevention: the "safety barrier" in high temperature environments

In fire or high-temperature leakage scenarios, hoses need to have self extinguishing and insulation capabilities:

Intrinsic flame retardant material: The outer layer is made of chloroprene rubber (CR) and aramid fiber composite material, with an oxygen index of 32%, far exceeding the 28% required by UL94 V-0 grade. In the simulated oil tank fire test, the hose burns continuously in an 800 ℃ flame for 30 seconds before self extinguishing, and there is no release of molten droplets or toxic gases.

Thermal insulation structure design: By adding a hollow glass fiber layer, the time for external heat to be conducted to the inner adhesive layer is extended to more than 5 minutes. For example, at a high temperature of 1000 ℃, the temperature of the inner rubber layer of a certain type of hose only rises to 120 ℃, far below the self ignition point of hydrocarbon media (257 ℃).

Fireproof coating technology: The outer surface is sprayed with a ceramicized silicone rubber coating, which forms a dense ceramic layer when exposed to high temperatures, blocking oxygen and heat. Experiments have shown that the coating can maintain the structural integrity of the hose in a 1200 ℃ flame for more than 30 minutes.

2.3 Intelligent Monitoring: From Passive Response to Active Warning

With the development of Industry 4.0, smart hoses have become a new trend:

Fiber optic sensor embedding: Integrating fiber optic in the enhancement layer to monitor real-time changes in strain, temperature, and pressure. A certain type of hose uses this technology to provide a 12 hour early warning of microcracks in the pipe body, avoiding major accidents.

RFID full lifecycle management: Each hose is equipped with an RFID chip to record production, testing, and maintenance data. Sinopec has increased the efficiency of hose maintenance by 40% and reduced the failure rate by 25% through this system.

Self diagnostic coating: The outer layer is sprayed with intelligent color changing material. When the pipe body is damaged, the coating color changes from green to red, achieving visual warning.

3、 10000psi pressure resistance: full field adaptation from land to sea

3.1 Land oil fields: balance between high-pressure transportation and wear resistance

In land deep well drilling and high-pressure water injection scenarios, hoses need to withstand a pressure of 10000 psi while resisting rock wear:

Size and flow compatibility: 3-inch hose is suitable for small drilling rigs, with a flow rate of up to 150m ³/h; 6-inch hose is used for ultra deep well drilling rigs, with a flow rate exceeding 500m ³/h. For example, the 6-inch hose used in Tarim Oilfield has worked continuously for 600 hours without leakage during operations at a depth of 8000 meters.

Wear resistant structure design: The outer layer adopts a nano silica reinforced formula, with a surface hardness of 95 Shore A and a wear rate of less than 0.05mm/100h in sand containing media. A certain type of hose has a service life of 1200 hours during drilling in the Junggar Basin, which is 60% higher than that of traditional products.

Quick connect system: equipped with integral union joints, the installation time is reduced to 1/5 of traditional flanges, reducing operational risks in high-temperature environments.

3.2 Offshore Platforms: Dual Challenges of Corrosion Resistance and Lightweight Design

The marine environment has higher requirements for hoses:

Salt spray corrosion resistance: The outer rubber layer is made of a blend system of ethylene propylene diene monomer (EPDM) and fluororubber (FKM), and has passed a 1000 hour salt spray test without corrosion. After 5 years of use on the Nanhai platform, the outer rubber layer of a certain type of hose remains intact.

Lightweight design: By optimizing the steel wire winding structure, the weight of 6-inch hoses is reduced to 280kg per piece (traditional products weigh about 350kg), reducing platform lifting costs.

Wind and wave resistance: Adopting a flexible joint design, it can withstand a 30 ° deflection angle and adapt to the dynamic displacement of offshore platforms. The experiment shows that this design can enable the hose to work normally under level 5 sea conditions.

Conclusion: Industrial Upgrade from Tools to Systems

With the expansion of the petroleum industry into deep-sea, polar, shale gas and other fields, anti-static API oil hoses are evolving from single pressure bearing components to intelligent monitoring systems. For example, hoses with integrated pressure sensors can provide real-time feedback on their working status, while self-healing inner adhesive layer technology can automatically fill microcracks below 0.3mm by releasing repair agents through microcapsules. In the future, with the integration of materials science and IoT technology, API certified hoses will become a key infrastructure to ensure energy security and promote Industry 4.0, providing more efficient and secure solutions for the global petrochemical industry.