Food hose production case.

Since cooperating with our company in December 2016, our company has provided food companies with 10000 meters of food hoses annually. Compared to the situation where the hose burst before cooperation, our product is more wear-resistant, antioxidant, and explosion-proof. And other features have improved the efficiency of mechanical use.

Oil extraction applications.

Since the cooperation in 2017, hydraulic oil drilling hoses have been widely used in this oil base, especially API-16C, API-16D, API-BOP, and ptfe large-diameter multifunctional hoses. The hydraulic system adopts the latest research and development achievements to strengthen the product. Compared with previous cooperation conditions, the characteristics of wear resistance, corrosion resistance, oxidation resistance, high and low pressure resistance have improved the efficiency of the machine and reduced the overall application cost.

Chemical hose applications.

The manufacturer has learned that our hoses are very suitable for the chemicals produced in our factory. Subsequently, the manufacturer began to order a large number of hoses and established a certain cooperative relationship with our company. The manufacturer also stated that the hose used before the cooperation had a shorter service life. Due to our company's ability to resist the strong acids and alkalinity of high-temperature chemical hoses, especially polytetrafluoroethylene hoses that can be used for more than 10 years, the production is also steadily increasing.

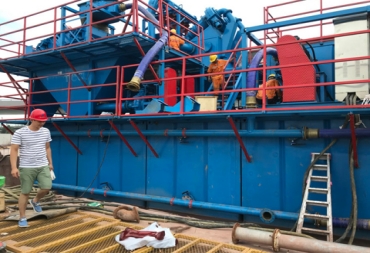

Mud treatment wear-resistant hose.

The customer's equipment is made of high-strength materials and can continuously filter a large amount of sludge. It has the characteristics of high processing capacity, high dehydration efficiency, and long service life. It is widely used in solid-liquid separation in various industries. The selection of wear-resistant hoses in the equipment is based on experimental and practical experience, and the selection of wear-resistant properties is optimized based on actual materials to ensure good service life.

Mud treatment equipment hoses.

This is one of the on-site cases of pile driving shield tunneling clients Length: 4-10m, inner diameter 150mm, pressure 20KG Medium: Shielding and piling mud, with a sand content of 25%, and a maximum particle size of 5mm in the hose; The hose is the supply hose that connects the mud pump and the mud team. Due to the irregularity of the material, wear resistance is required; It is currently designed for this client. The customer has been working continuously for 1.5 years and has not been replaced.

High pressure steel wire wrapped hose.

The company has established a long-term supply relationship with a leading company in Hunan Heavy Industry. The product involves wire weaving and wire winding. Company leaders have visited our factory multiple times. The MT98 mining steel wire winding hose produced by our company is suitable for hydraulic supports in coal mines and comprehensive coal mining. Hydraulic systems such as units have obtained coal safety certification, and hoses can transport mineral oil, water-based hydraulic oil, or water. The supply failure rate of hydraulic hoses has decreased to 0.08%.

Spray concrete sandblasting hose.

Ltd. is a mechanical equipment manufacturing enterprise engaged in the research and development and production of concrete spraying anchor support equipment. Our company has long-term production of sandblasting machines, spraying machines and their accessories, involving sandblasting, spraying and other equipment. The company is headquartered in the high-tech gathering area of the ancient capital Xi'an, with a production area of 100000 square meters of nozzles and sandblasted concrete.

Suction and discharge hose engineering.

An engineering company in Henan established a cooperative relationship with our company in 2016. The company has long supplied suction and drainage hoses, sandblasting hoses, and ultra wear-resistant UPE inner membranes, making them outstanding in corrosion resistance, acid and alkali resistance, with an annual supply of tens of thousands of pieces. M. Received high praise, the suction and drainage hose has characteristics such as resistance to negative pressure and corrosion, meeting the harsh environment and conditions of customers.

High pressure air hose.

High pressure air hoses are mainly used for high-pressure air transportation, compressors, etc. In 2015, our company established a cooperative relationship with a large shipyard with an annual production capacity of 10000 meters. Long term supply of air hoses, hydraulic hoses, raw materials, nitrile rubber, and traditional rubber hoses. It has obvious aging resistance and will not show uniform cracking on the surface when used outdoors for more than five years.