The petroleum industry has strict standards for the selection of rubber hoses due to its unique working environment and chemical processing requirements. The following are several common types of rubber hoses in the petroleum industry, as well as their characteristics and applications:

Oil resistant rubber hose

Material and structural characteristics

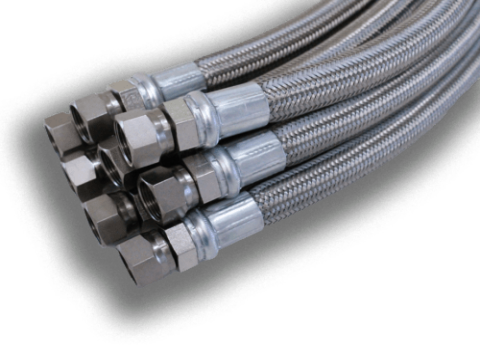

Oil resistant rubber hoses are usually made of nitrile rubber, which has excellent resistance to petroleum products and various chemicals. Its structural design includes multiple layers of synthetic fiber wires and steel wire spirals to enhance its durability and burst strength in high-pressure environments. The design of this hose ensures reliability under high pressure and durability requirements.

application area

Oil resistant rubber hoses are widely used in fields such as oil fields, gas stations, and petrochemical plants for transporting petroleum, diesel, lubricants, and some chemicals. Its oil resistance makes it an ideal choice for these applications, especially in environments that require long-term exposure to oils and chemicals.

High temperature resistant steam hose

Material and temperature resistance performance

High temperature steam hoses are generally made of specially formulated chloroprene rubber or silicone rubber, which can withstand temperatures up to+200 ° C. It is usually embedded with high-temperature resistant synthetic fiber mesh inside, providing necessary structural support and preventing excessive expansion of the hose at high temperatures.

application area

In the process of petroleum refining, high-temperature steam is often required, and high-temperature steam resistant rubber hoses are mainly used to transmit hot steam or hot water. For example, in cleaning pipelines, driving turbines, or heat exchange applications, such hoses can ensure normal operation under extreme temperature conditions.

Acid and alkali resistant chemical hose

Material and chemical stability

Acid and alkali resistant chemical hoses are usually made of special rubber materials such as fluororubber or hydrogenated nitrile rubber, which provide excellent chemical corrosion resistance. This type of hose is designed for use in environments containing strong acids, alkalis, or other corrosive substances, and can withstand the corrosion of these chemicals without damaging its structure.

application area

In the process of petroleum refining and chemical processing, it is often necessary to deal with various corrosive substances. Acid and alkali resistant chemical hoses are mainly used for transporting corrosive chemicals, acids, alkalis, etc. They protect pipeline systems from corrosion when dealing with these extreme chemicals, ensuring safe operation and long-term stable system operation.

epilogue

In summary, the petroleum industry mainly uses specific types of rubber hoses such as oil resistant rubber hoses, high-temperature steam resistant rubber hoses, and acid alkali chemical resistant rubber hoses due to its unique working conditions and chemical processing needs. Each type of hose is designed with specific materials and structures to adapt to different environments and chemical challenges, ensuring efficient and safe operation in the petroleum industry. Correctly selecting and using suitable rubber hoses is an important part of ensuring the normal operation of the petroleum industry.